Best quality for a better interior

Based on the designer’s style drawings, we use to conduct the study of the seat and add to it our devices, such as ATC’s drawers or flaps.

Seats are maybe the most important fourniture in an aircraft. ATC use to make conception who integrates all the constraints to satisfy the technical wishes of the manufacturer and obviously bring the attended comfort to the final client.

Making born a aircraft seat is the conjunction between several professions. ATC knows them and is able to accelerate the study in a co-working dialog flux.

ATC perfectly knows aircraft standards limitations for TTOL seats and makes usable 3D CAD designs in the respect of designer’s 2D or 3D style specifications.

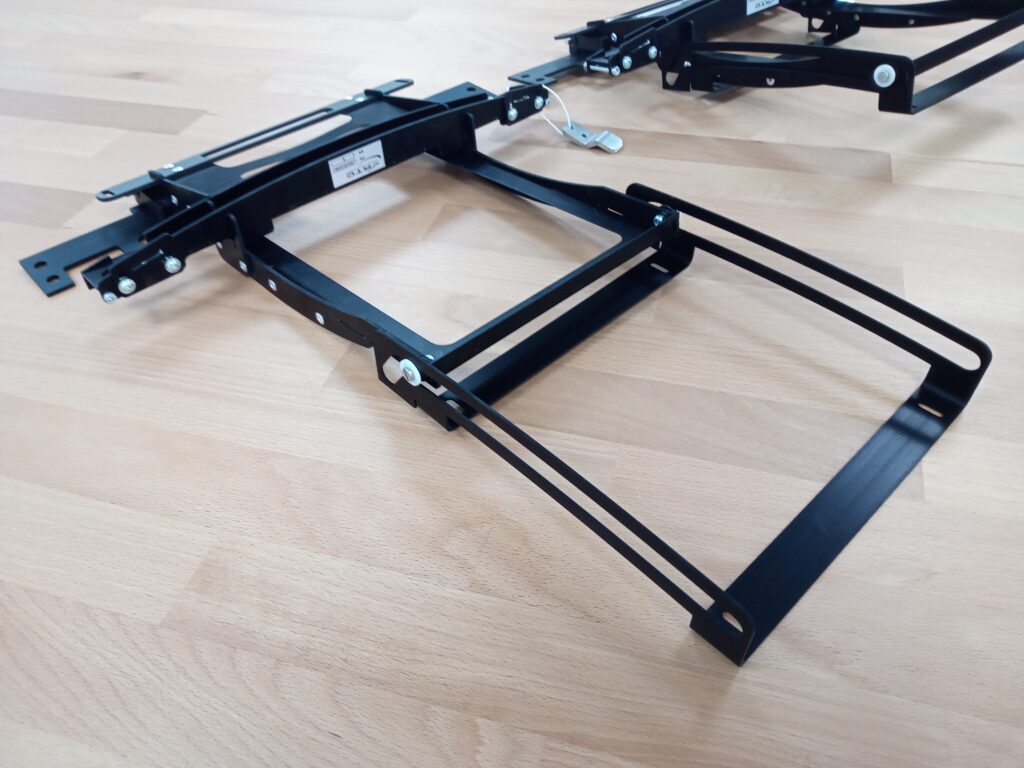

Stacking and foam density choice, leather edges strategy, elements to structure linking, accessories integrations,… are known by ATC which also brings some modern solutions and advices to dissimulate as possible mechanical structure.

Structural seat parts are made from honey comb boxes in which we can, in most of the cases, integrate robust accessories that ATC can provide.

The style surfaces are therefore protected as possible.

These boxes are coated by differents materials like foam, leathers, fabrics, inlay who are integrated in our 3D CAD.

All of these final parts can be directly machined or 3D printed to accelarate making of prototype and final seats.

Classical accessories are Flaps, Drawers and backrest solid shroud but ATC can provide custom buttons, plugs, levers who are well integrated in different platted finishing styles.

Flap

Drawer

Backlighted

custom switch

Shroud mechanism

Shroud mechanism